In modern automotive and industrial systems, real-time data transmission is crucial. Rosenberger’s HFM® “Mini-Coax” connectors support frequencies up to 20 GHz and data rates to 28 Gbps, yet demand exacting termination techniques that few workshops can offer . Without the proper crimping fixtures, calibration jigs and optical inspection tools, attempts to terminate these connectors often lead to signal loss, intermittent faults and costly downtime .

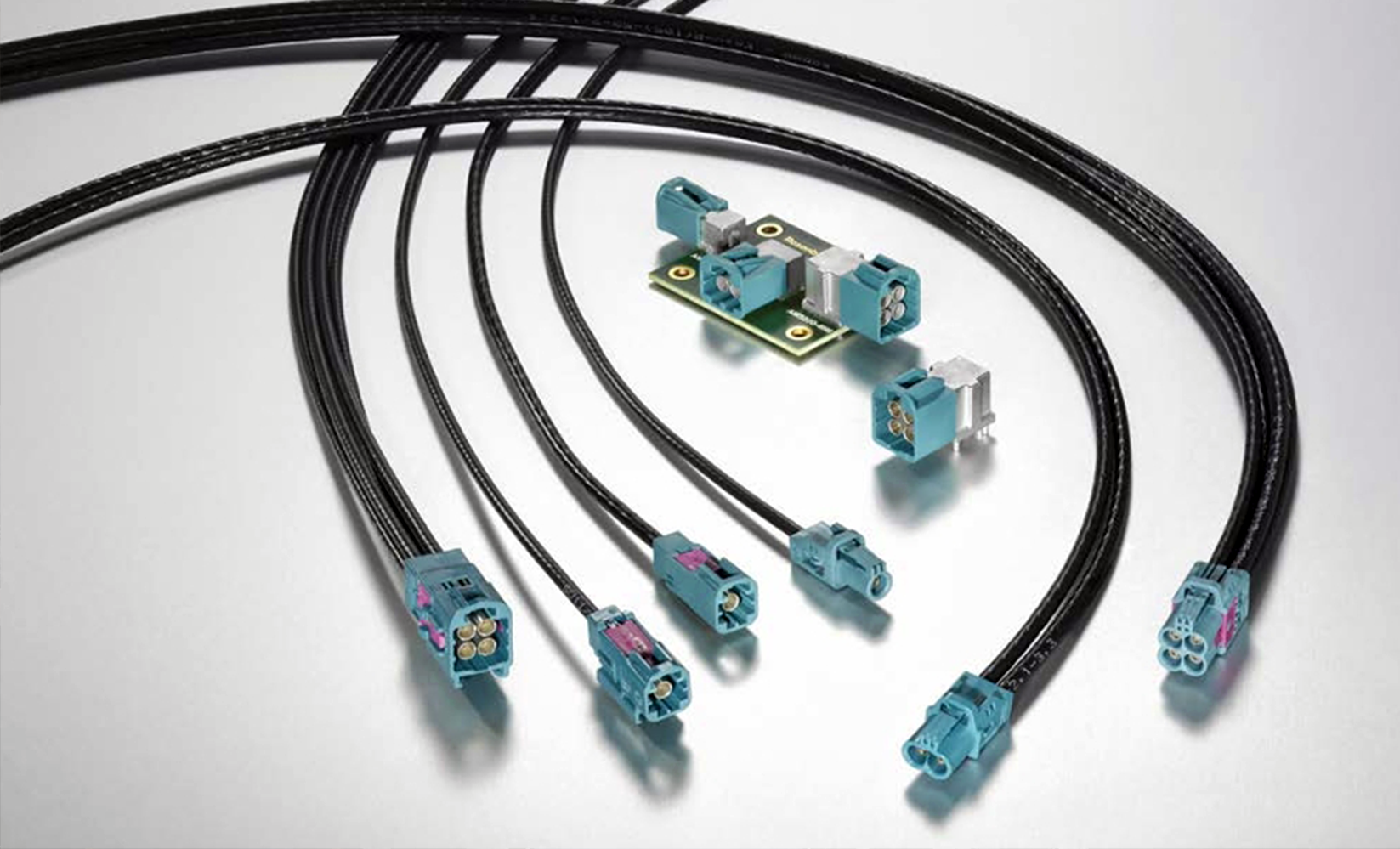

Rosenberger HFM® assemblies deliver up to 80 % space savings versus conventional FAKRA connectors, making them ideal for compact applications such as ADAS head units, infotainment links and sensor networks . However, their stamped-and-formed contacts and tight tolerances require specialist tooling—precision adaptors, repair tool kits and test-board rigs—that most service providers simply do not possess.

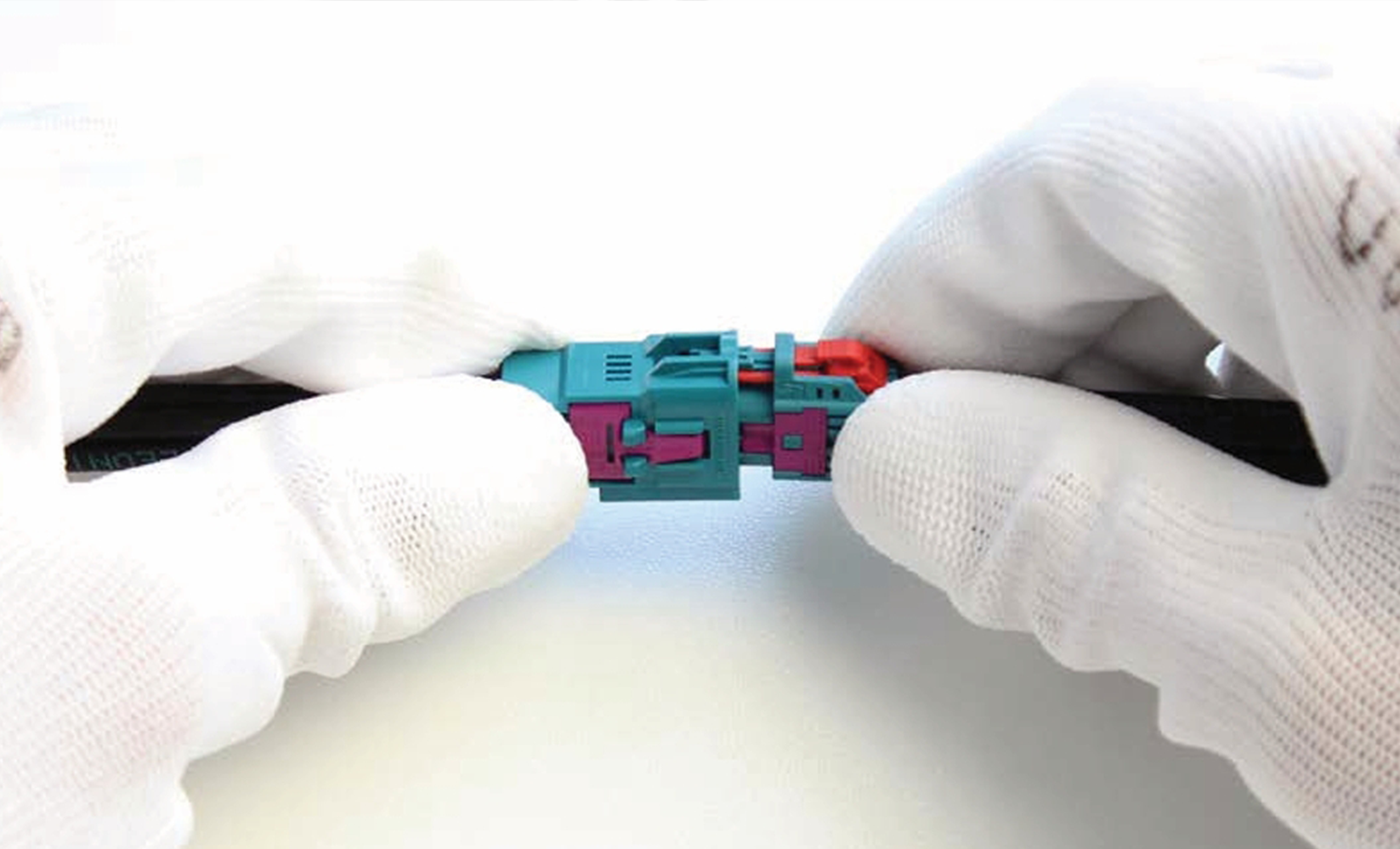

At Hadfield Services we have invested in the full range of Rosenberger-approved tools and trained our technicians to OEM standards. Our workshop carries dedicated HFM® crimping fixtures, pull-test machines and high-magnification inspection microscopes, ensuring every termination meets Rosenberger’s technical data and automotive standards. This capability sets us apart: where others turn away complex HFM® jobs, Hadfield Services delivers flawless assemblies on prototype and production scales.

Each harness we produce undergoes multi-stage quality checks: visual inspection under 30× magnification, continuity and insulation resistance tests, followed by mechanical pull and torque verification. This rigorous process aligns with our digitalised “How” framework for engineering excellence, guaranteeing consistency and compliance with IATF 16949 and ISO 14001 certifications.

Don’t risk signal integrity or face delays due to inadequate tooling. Partner with Hadfield Services to benefit from our unique HFM® termination expertise, reduce rework and accelerate your project delivery.

High-Speed FAKRA-Mini

Rosenberger HFM® (High-Speed FAKRA-Mini) is Rosenberger’s “mini-coax” connector system designed for the automotive industry. It supports frequencies from DC up to 20 GHz and data rates as high as 28 Gbps, all within a footprint that can save up to 80 per cent of space compared with conventional FAKRA connectors .

Key features include:

-

Impedance: 50 Ω, optimised for high-frequency transmission

-

Return loss: ≥ 25 dB up to 3 GHz, ≥ 20 dB up to 6 GHz, tapering to ≥ 10 dB at 20 GHz

-

Mating cycles: ≥ 25 (standard), with waterproof variants rated ≥ 5 cycles

-

Mechanical robustness: precision-stamped contacts, optional Connector Position Assurance (CPA) to prevent disengagement

Typical applications span advanced driver-assistance systems (ADAS), infotainment links, sensor networks and any environment demanding real-time high-speed data transmission in a compact form. Hadfield Services’ investment in the specialist crimping fixtures, calibration kits and test-board rigs required for HFM® termination means that, while few workshops are equipped to handle these connectors, we can deliver perfectly assembled HFM® harnesses every time.

Most workshops lack the specialist crimping fixtures, calibration jigs and inspection tools required to terminate Rosenberger HFM® connectors. At Hadfield Services, we’ve invested in the full range of Rosenberger-approved equipment and technician training to deliver flawless, high-frequency terminations every time.

What do you think?

The amount of funding they secured is impressive, and it’s great to see that they have the support of investors to help them bring their vision to life. This financing will surely help them to accelerate the development of Big River 2 and make it a success.